Ain't nothing here yet. Go 'way

When most people buy a printer or a printer kit it's for a specific printer setup. The kit has extrusions for one frame size, it has motors and electronics for one motor and gantry setup, and one specific extruder. I'm trying to do something a little different with this printer 'system'. I'm not going to give you specific instructions and a BOM to build a single printer but rather parts, guidelines, and tools to build your printer your way!

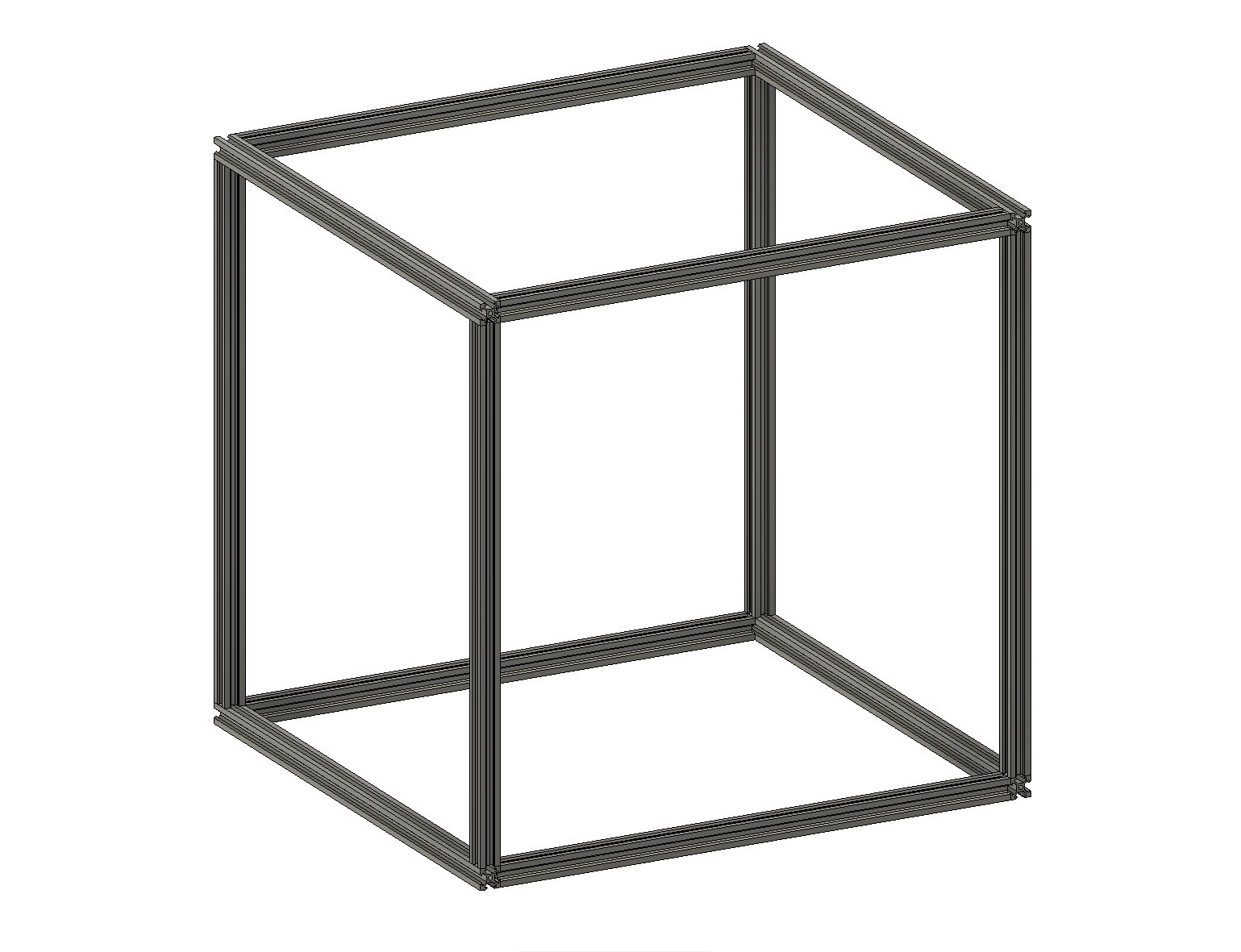

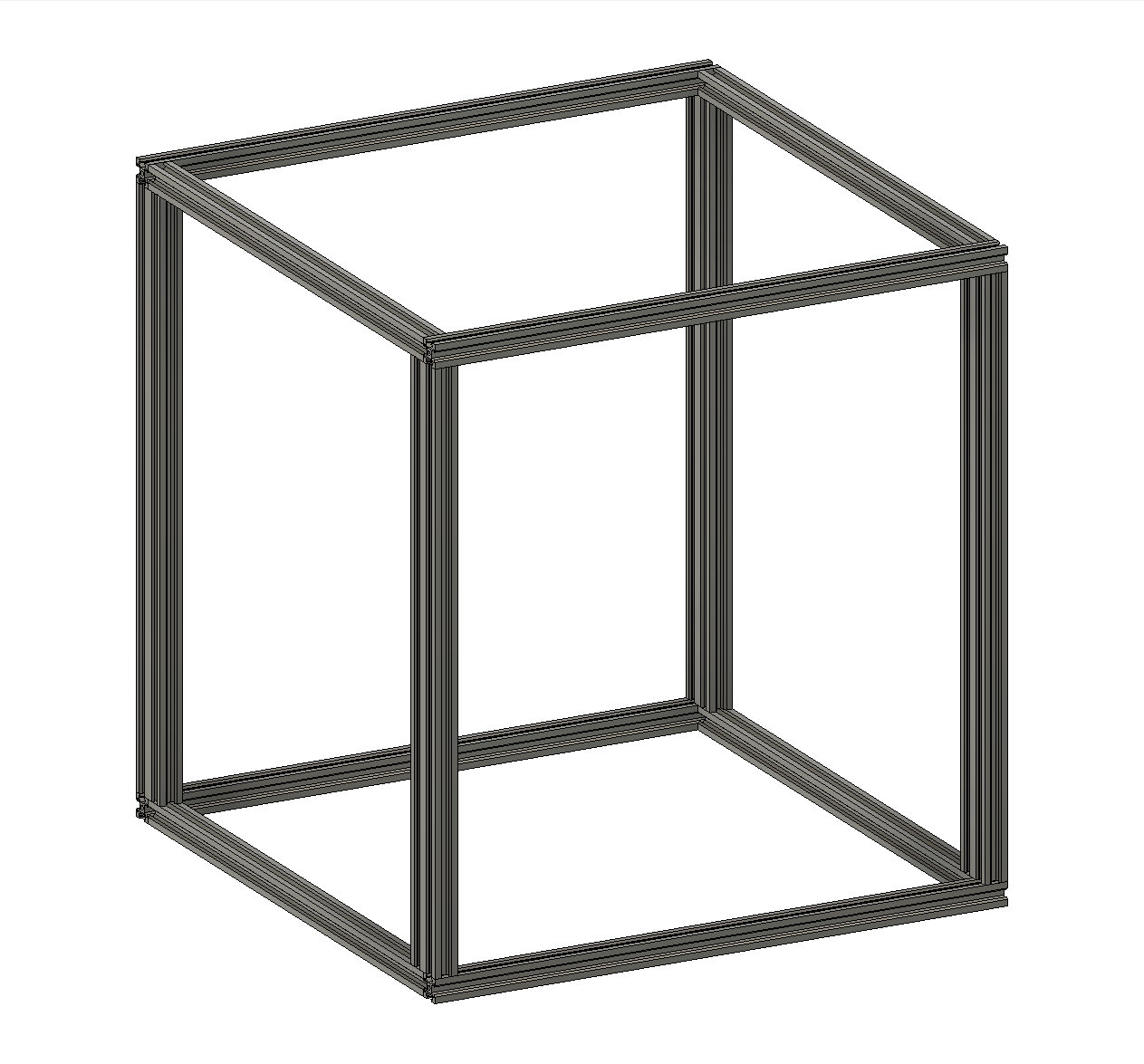

At its core, the system is a cube-style printer with a fixed Core XY gantry and vertically moving bed. If you're looking for a bed slinger, delta, belt printer, or something even more unique then you may need to look elsewhere.

All of the components use off-the-shelf parts that are easibly obtainable through common marketplaces like Amazon and Ebay. While I can offer a number of options throughout the build for common setups I've also tried to keep these parts simple and easy to modify if you want to expand beyond what is already available. I'll include links (affiliate where available and purchasing through those links is greatly appreciated) to parts that I have personally used however you should be able to equivalent parts easily through your preferred vendors.Good luck and have fun!

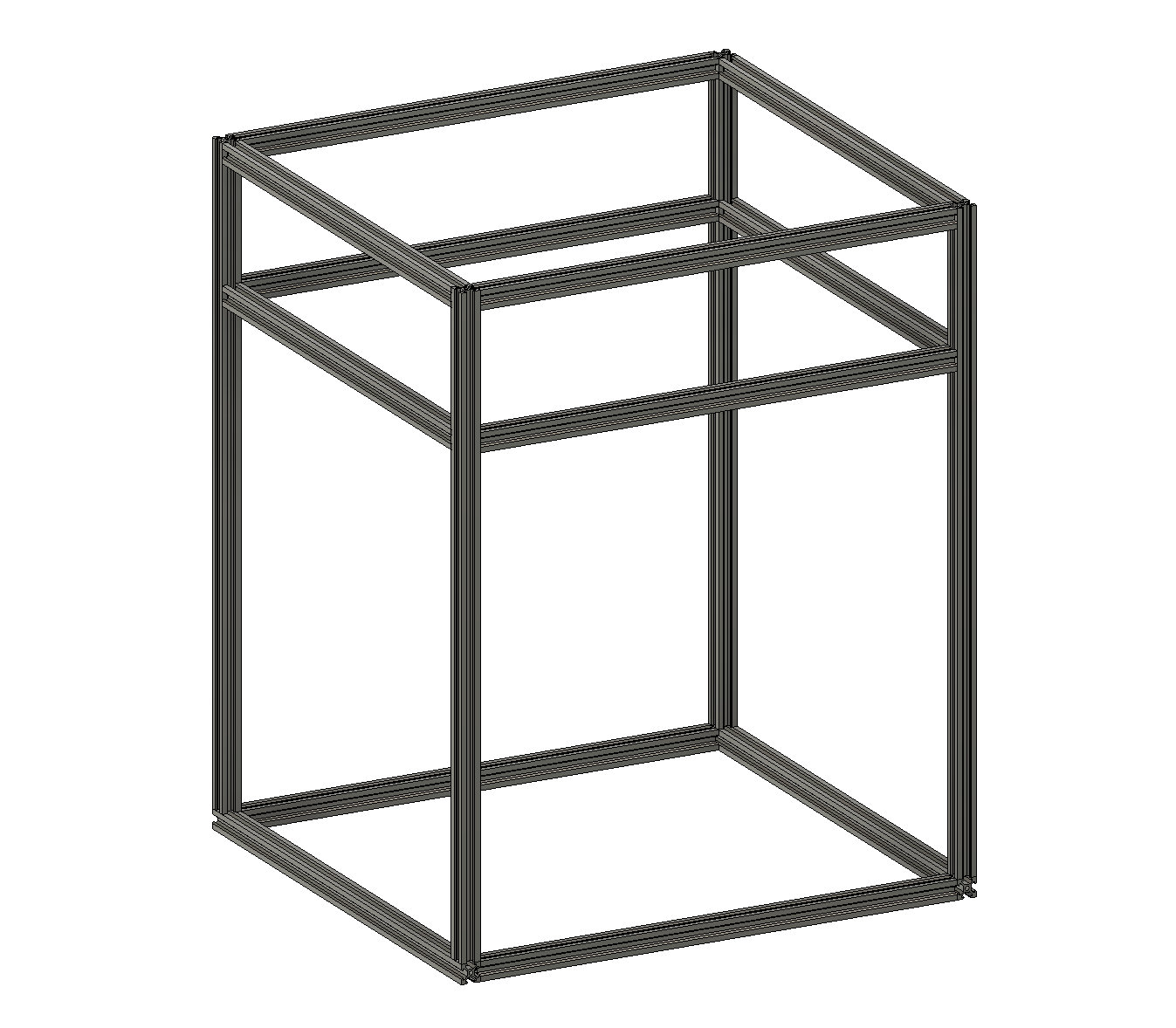

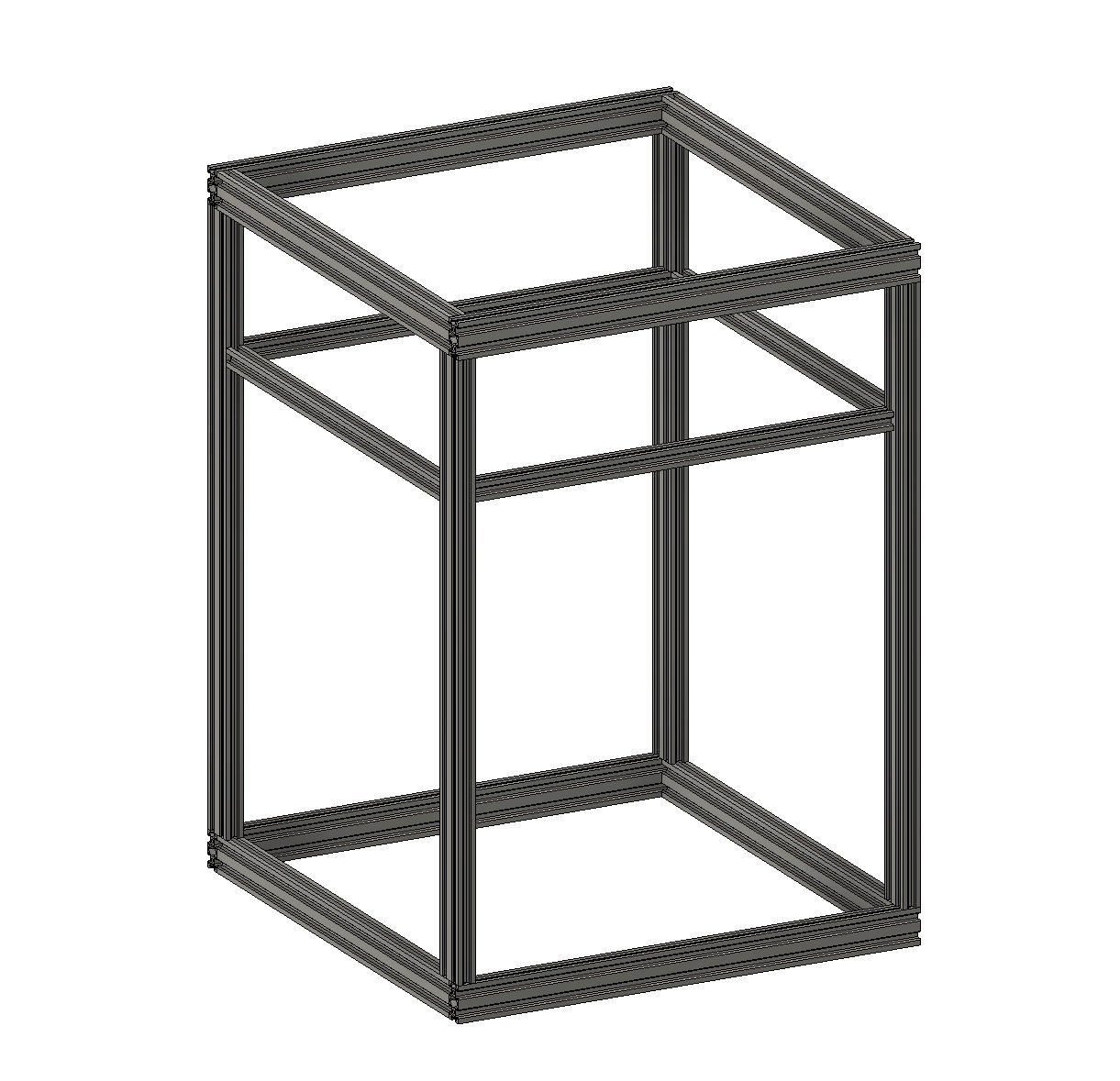

The printer system calls for a 2020-based cube frame although 2040 can also be used with some caveats. The most basic 2020 cube frame uses twelve extrusions with three sets of four that share the same length (eg: 4x500mm, 4x450mm, 4x400mm = 12).

The length of the extrusions determine the maximum build volume of the printer. All of the gantry hardware fits within the frame so when you're planning your printer size assume you will lose ~180mm in the X and Y direction and ~200mm in the Z direction from the interior of the frame - although the exact spacing may vary depending on the exact hardware you use.

One of the hardest pieces to source is the build plate so you will likely start with the plate - roughly equivalent to your x/y build volume - and plan everything else from there. While you can get custom milled aluminum plates the easiest and cheapest option is to utilize a plate from another printer of similar size.

In addition to the basic 2020 cube this system should also support a number of structurally enhanced cubes. A common upgrade is to use 2040 extrusions on the verticals (eg: TronXY X5SA, Ender 5). This will work fine although you may have to flip the pulley blocks upside down.

Some printers use a 'ladder' style design for their side panels (eg: Folgertech FT-5). I really like this design as the extra offset extrusions add a lot of rigidity - more than just upgrading some to 2040 - and the additional Z space on top can be used to hold cameras, tools, pulley looms, etc. The printer system allows for passing-through the extrusions on the motor and pulley blocks and works fine with this design.

And if you really wanted to get solid, you can combine a 2040 outer frame with 2020 ladder rungs and you'll have a bomb-proof setup.

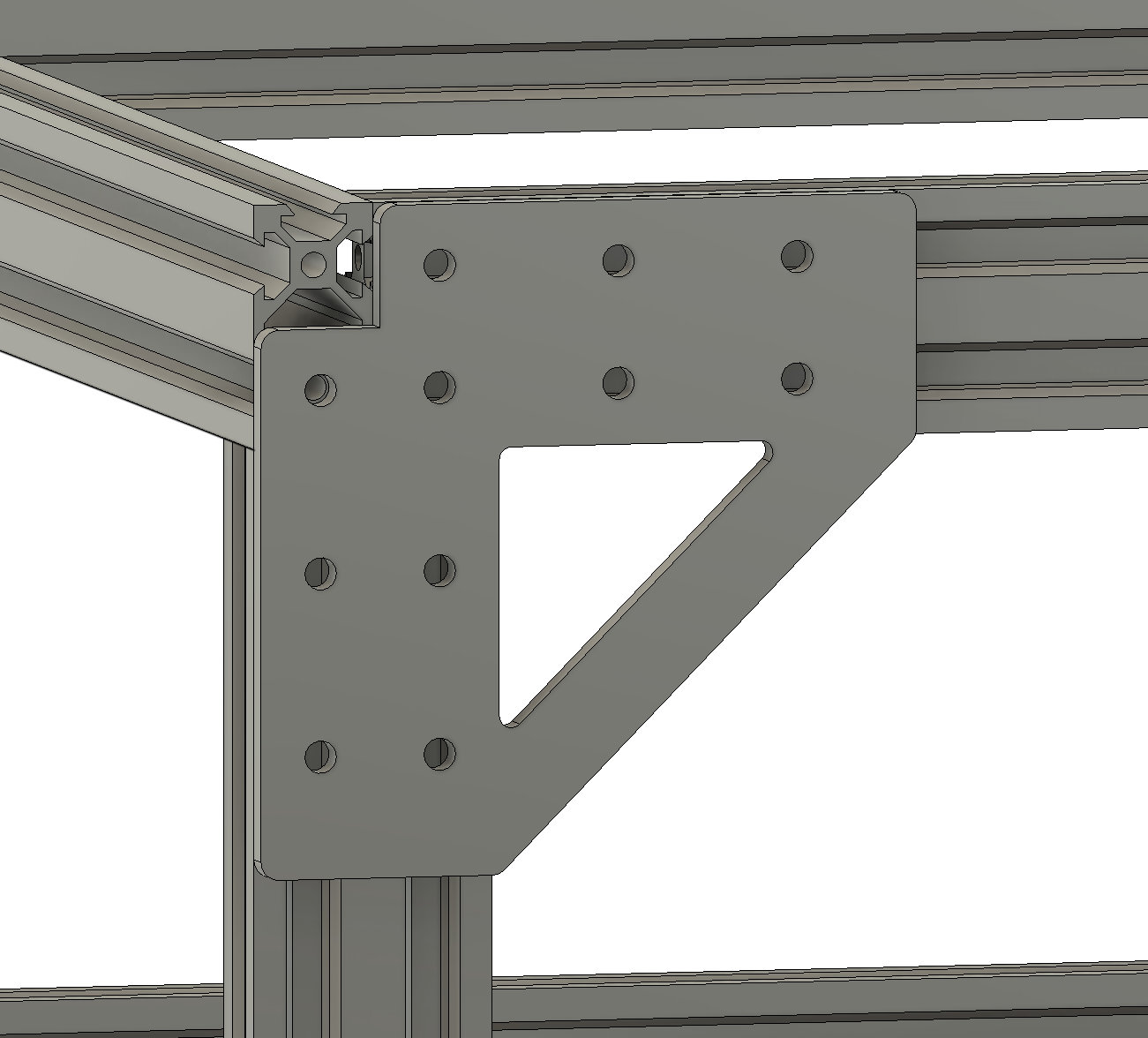

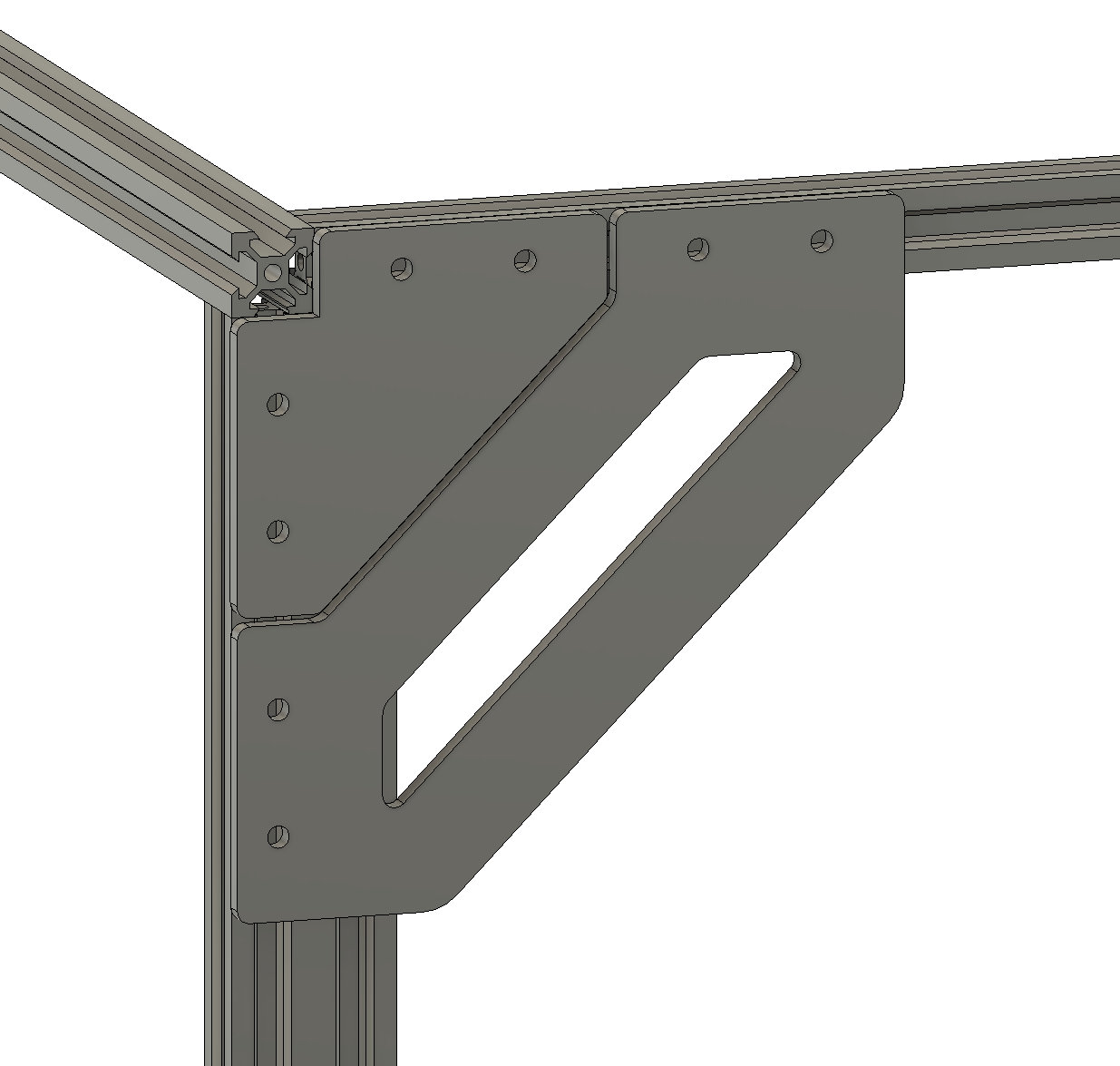

There are a variety of ways to join 2020 and 2040 extrusuions to make corners. It's common to see end-tapped 2020 extrusions and holes drilled through extrusions to hold frames together. I'm not a huge fan of this approach as drilling is permanent and aluminum threads aren't super strong long-term. If we avoid tapping and drilling the next most common attachment method seem to be 2020 and 2040 interior corners followed by L plates. My personal preference is to use both aluminum 2040 interior corners (yes, on the 2020-to-2020 joints) as well as L-plates. The L-plates are handy for alignment and the aluminum corners really lock the joint in. You can get L and T plates in aluminum and steel however that may be overkill if you're also using interior corners. I have a selection of plates you can utilize:

Basic 2020 Corner Plate:

Basic 2040 Corner Plate:

2020 to 2040 Corner:

And an extended corner for when you need exta support or alignment:

2040 Corners (recommended over 2020 Corners)*

Zyltech 400mm Aluminmum Bed Kit

The print system supports two different setups for the Z-gantry; a two-motor setup common in cube-style printers and a three motor system for completely automated bed leveling. Each has significantly different requirements for attaching to the vertical rods as well as to the bed platform